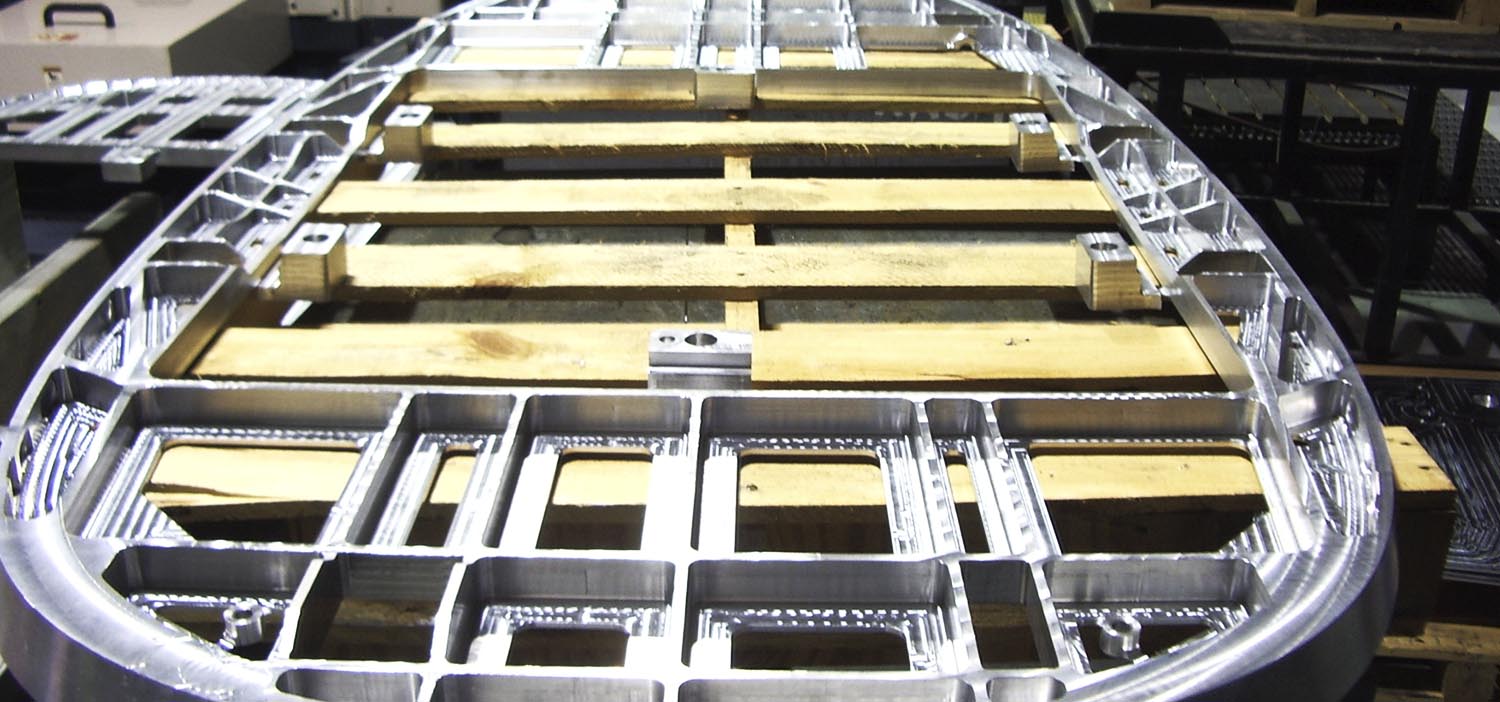

Jormac’s multiple 3-axis machining centers provides us full CNC machining capability, which supports a variety of operations from one off custom gussets to production runs of small to large complex parts, aluminum lay-up molds, and high tolerance trim fixtures. We are able to fabricate metal parts up to 30” wide by 60” long, and even larger with multiple set-ups. Utilizing the full capabilities of Pro-E Manufacturing and Surfcam we can fabricate extreme contoured parts.

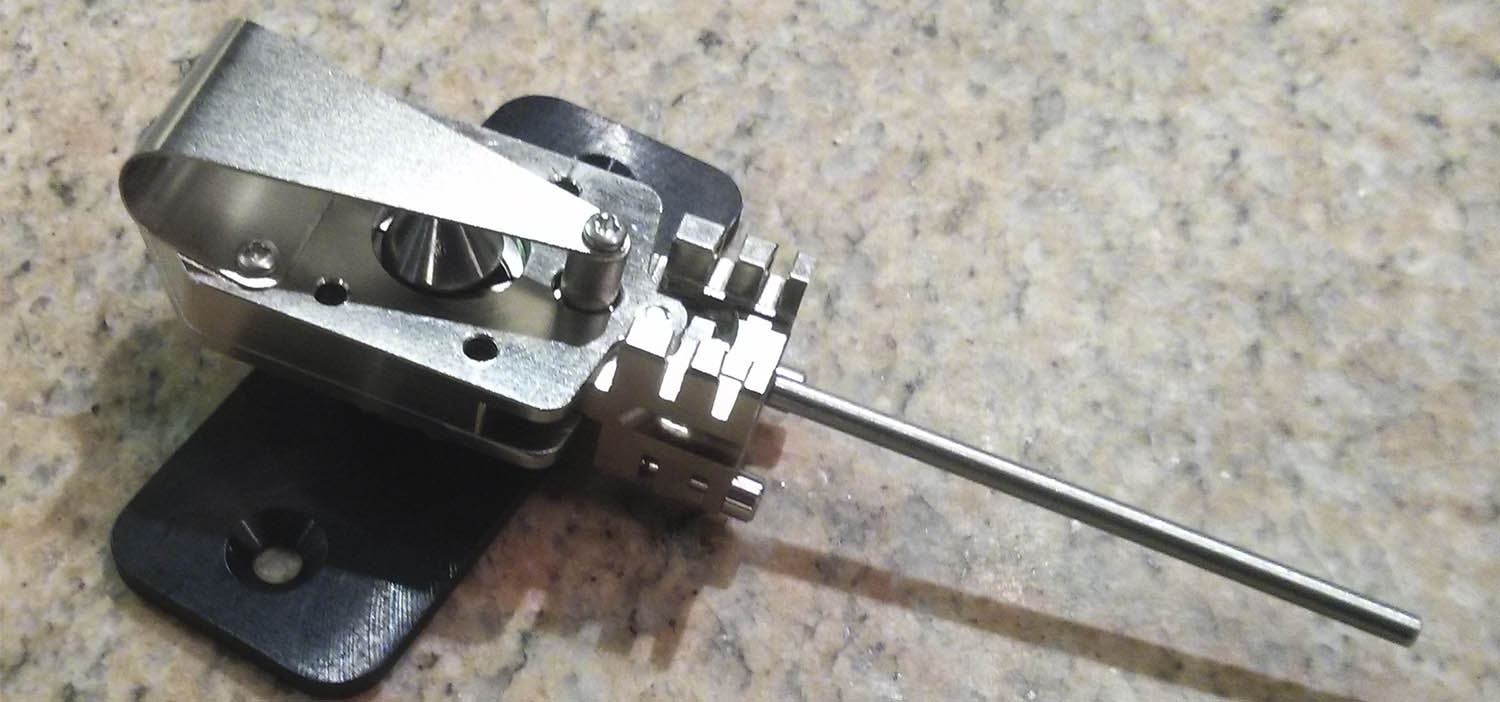

Our goal is to deliver an exceptional product; therefore, we take care to prep the part for the final operation whether it is anodized, painted or plated. Other equipment such as our 8 foot 100 ton press brake compliments our CNC mills to enables us to manufacture a large array of light weight formed brackets.

Our In-house part manufacture capabilities ensure quick response times on last minute liaison part requirements. Jormac manufactures the components, assemblies and complete installation kits for each of our engineering design deliverables.