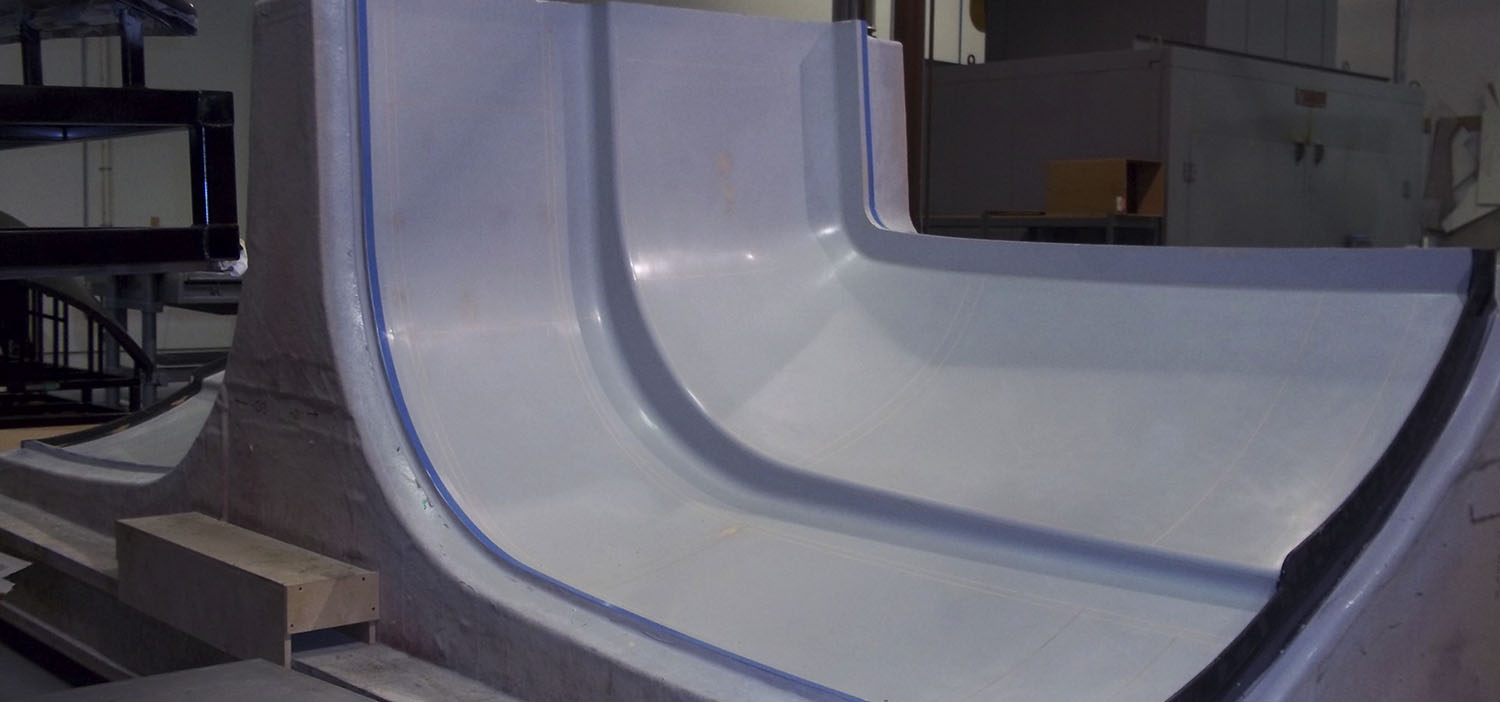

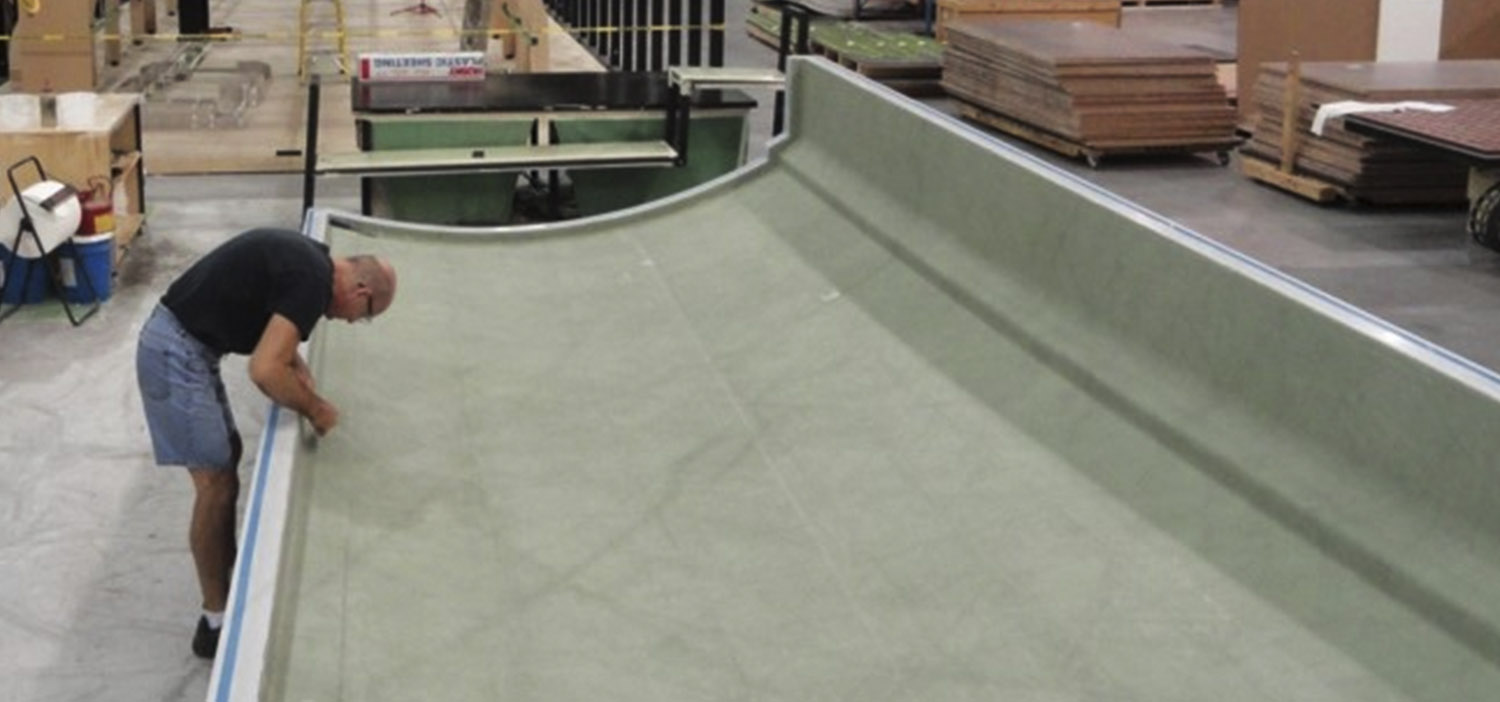

Jormac Aerospace is the industry leader in the tooling mold design and manufacturing for composite components. The in-house production engineering team located in Tampa Bay designs our molds and tooling to handle any specific production cycles, volumes, dimensions, and processing conditions based on customer and/or project requirements.

- Wet layup molds

- VARTM layup molds

- Hi-temp foam tooling

- 3D printed tooling

- Aluminum & nickel tooling

- Research & development

Jormac has an extensive inventory of tooling molds which provide “off the shelf” solutions for numerous lining panel shapes and contours. Jormac recognizes that in addition to achieving the highest quality possible, cost and schedule are the next two most significant considerations for any interior completion, reconfiguration, or refurbishment project. By providing a large tooling mold selection, Jormac is offering a proactive solution which addresses all these key factors. Of course, we recognize there are more often than not, unique requirements which must be satisfied. Jormac offers complete in-house tooling mold design and fabrication capability to meet the most demanding customer requirements.